مواد رنگزای دیسپرس

Disperse dyes can be used for dyeing and printing polyester, acetate, triacetate, nylon and acrylic. The colour shade card contains information on various properties of application

These dyes are eminently used for making self shade as well as compound ones. They provide high tinctorial strength, good leveling and favourable reproducibility for dyeing and printing

Our disperse dyes can be classified into the following three groups

(E) Subzero type: Dyes which show excellent leveling property and are applied mainly at high temperatures

(SE) Medium temperature type: Dyes which show high fastness properties, especialy light fastness and are applied with any dyeing process

(S) High temperature type: Dyes which show excellent sublimation fastness and can sufficiently stand hard treatment processes after dyeing, such as pleat and permanent press finishing. They are applied mainly to high temperature dyeing, themosol dyeing and printing. Finally, dyes of our corporation are a series of disperse dyes which have been marketed for synthetic fibers, especialy polyester fibers

Dyeing methods

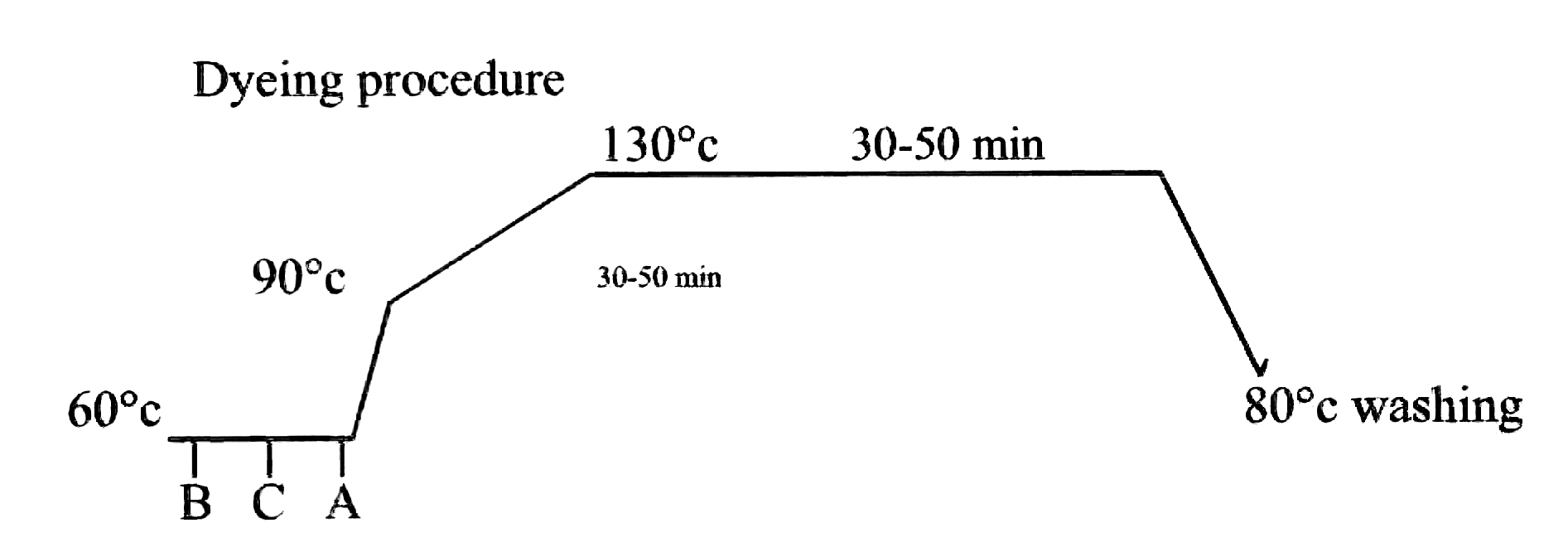

High temperature dyeing method *

A. Dyes :x% (o.w.f)

B. Leveling agent :0.5-1g/l

C. PH : PH 4.5-5 (adjusted with acetic acid 0.25 g/l and sodium acetate 1g/l)

Temp.,Time : Riase the temperature from 90c to 130c in 30-50 min and dye for 30-50 min at 130c

Liquor ratio : 1:10~30

Reduction clearing :Hydrousulfite cc.1g/l

Naoh (40 BE)2 m/l

Nonionic surfactant 1 g/l

Liqour ratio1:30

Temp,Time 85c X 10min

Dyeing procedure

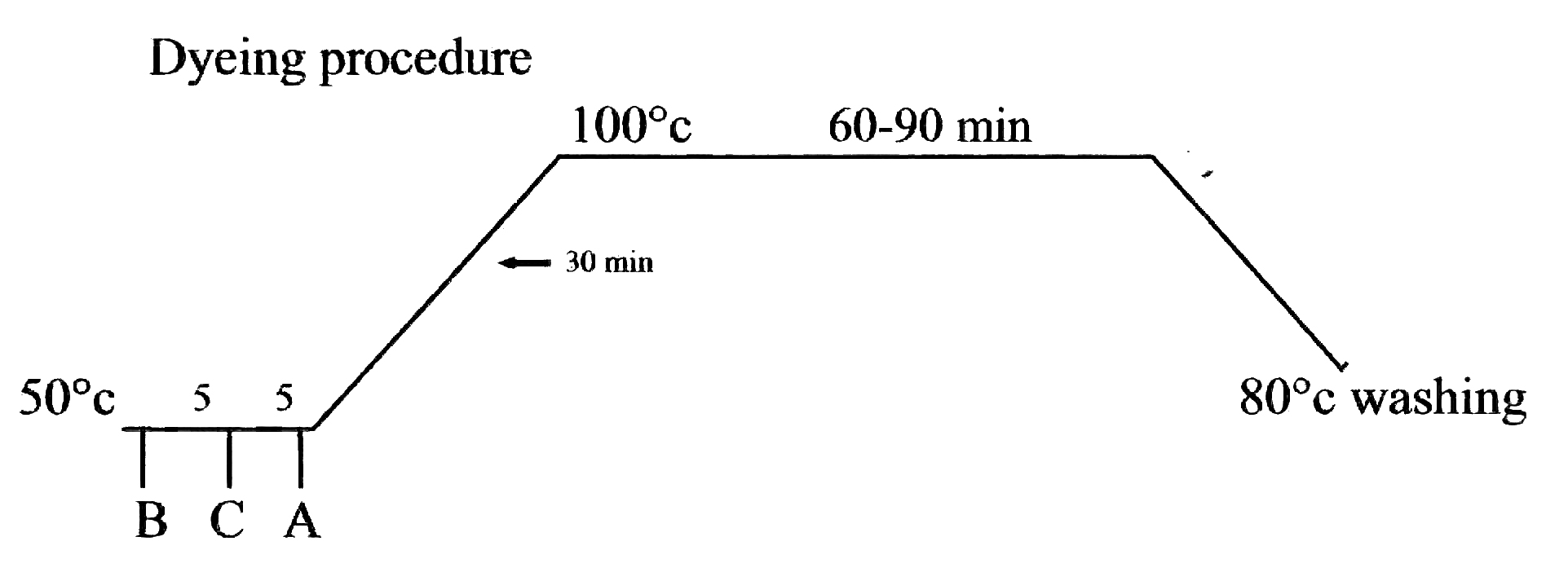

Carrier dyeing method *

A.Dyes : x % (o.w.f)

B.Carrier : Carrier P cone 4g/l

C.PH : PH 4.5-5 (adjusted with acetic acid 0.25 g/l and sodium acetate 1 g/l)

Temp, Time : Raise the temperature from 50c to 100 c in 30 min and dye at the boil for 60-90 min

Others : Same as in high temperature dyeing

Printing method *

Material : Polyester fabric

Printing paste: Disperse dyes xg

Water : 250g

Stock Thickening (locust bean gum type) 550 g

reduction : 2 g

inhibitor (sodium chlorate)

Tartaric acid : 3 g

Balance (water or thickener) : y g

Total : 1000 g

For reduction printing depth, the above printing paste is mixed to the following reducing thickening

Reducting : Stock thickening 700 g

Thickening : Water 293 g

Reduction inhibitor 4 g

Tartaric acid 3 g

Total 1000 g

Proced: Printing → Drying → H.P.Steaming (130 c × 30min) → Rinsing → Reduction clearing → Rinsing → Dryeing

Thermosol dyeing method *

Material : Polyester fabric

Dyeing depth : X g/l

Migration inhibitor Sodium alginate 1 g/l

Proced : Preparation of padding liquor → Padding → ureSqueezing (Pick-up 60-70%) → Intermediate drying (110 c × 60 sec) → Thermosoling (180 c ~ 220 c × 90sec) → Rinsing → Reduction clearing → Rinsing → Drying

Test method of physical properties

Light: Iso – 105/BO2

Wahsing : Iso – 105/CO3

Rubbing: Iso – 105/X12

Sublimatio: Iso – 105/POI

Perspiratio: Iso – 105/EO4

For reference only

Note

Very Suitable ○ Sutiable Δ Less Suitable X Not